In order to participate in the GunBroker Member forums, you must be logged in with your GunBroker.com account. Click the sign-in button at the top right of the forums page to get connected.

These Are Not Millennials

buschmaster

Member Posts: 14,229 ✭✭✭

buschmaster

Member Posts: 14,229 ✭✭✭

http://www.stltoday.com/news/archives/a-look-back-how-st-louis-workers-kept-the-ammo/article_3485624f-ef86-51ee-b100-858060b47c9f.html#15

as of 1940 the United States had not yet entered the war, but were helping the Allies. it would cost $110,000,000 to build the plant: 300 buildings on 291 acres, employing 17,000 construction workers.

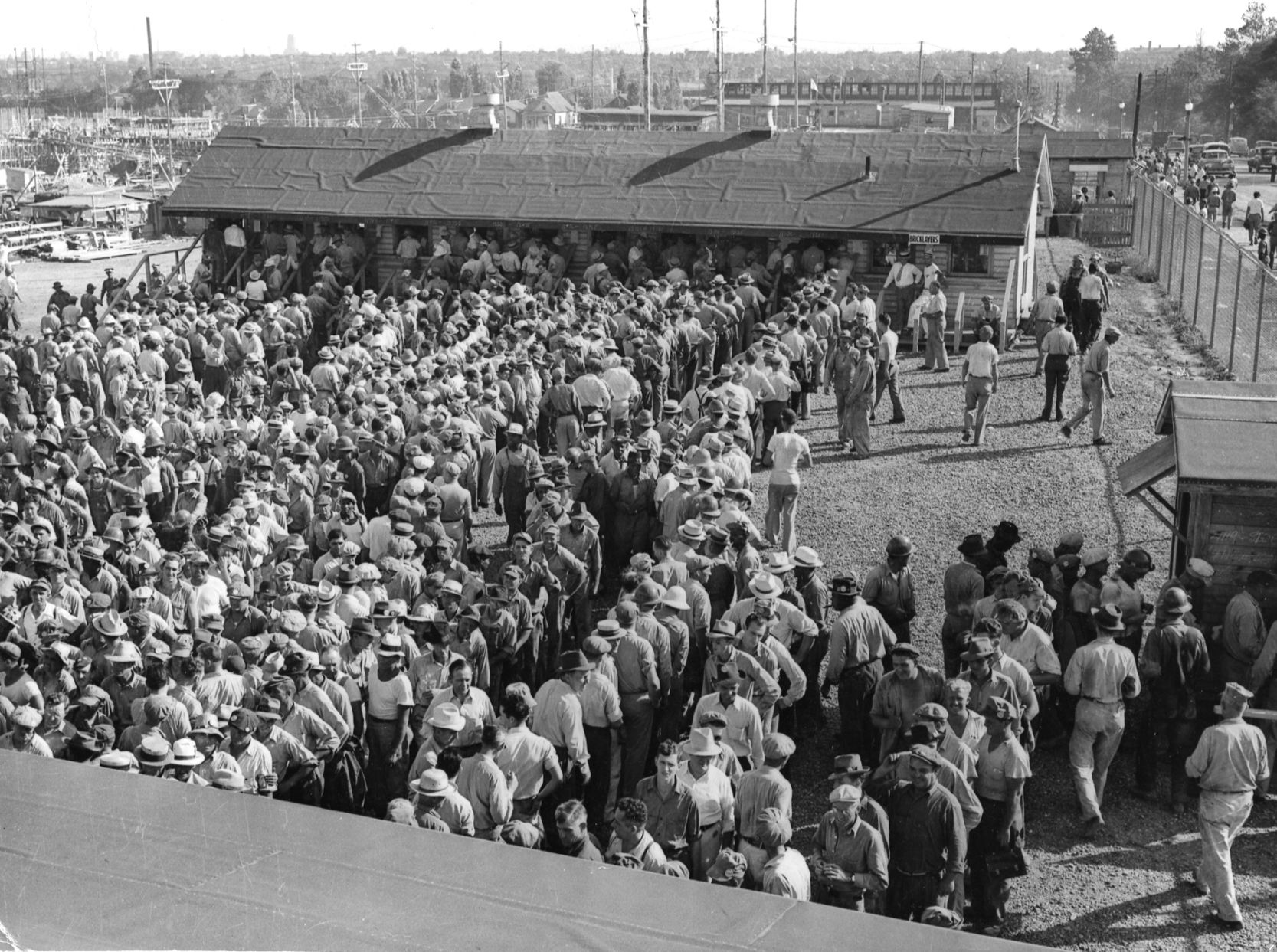

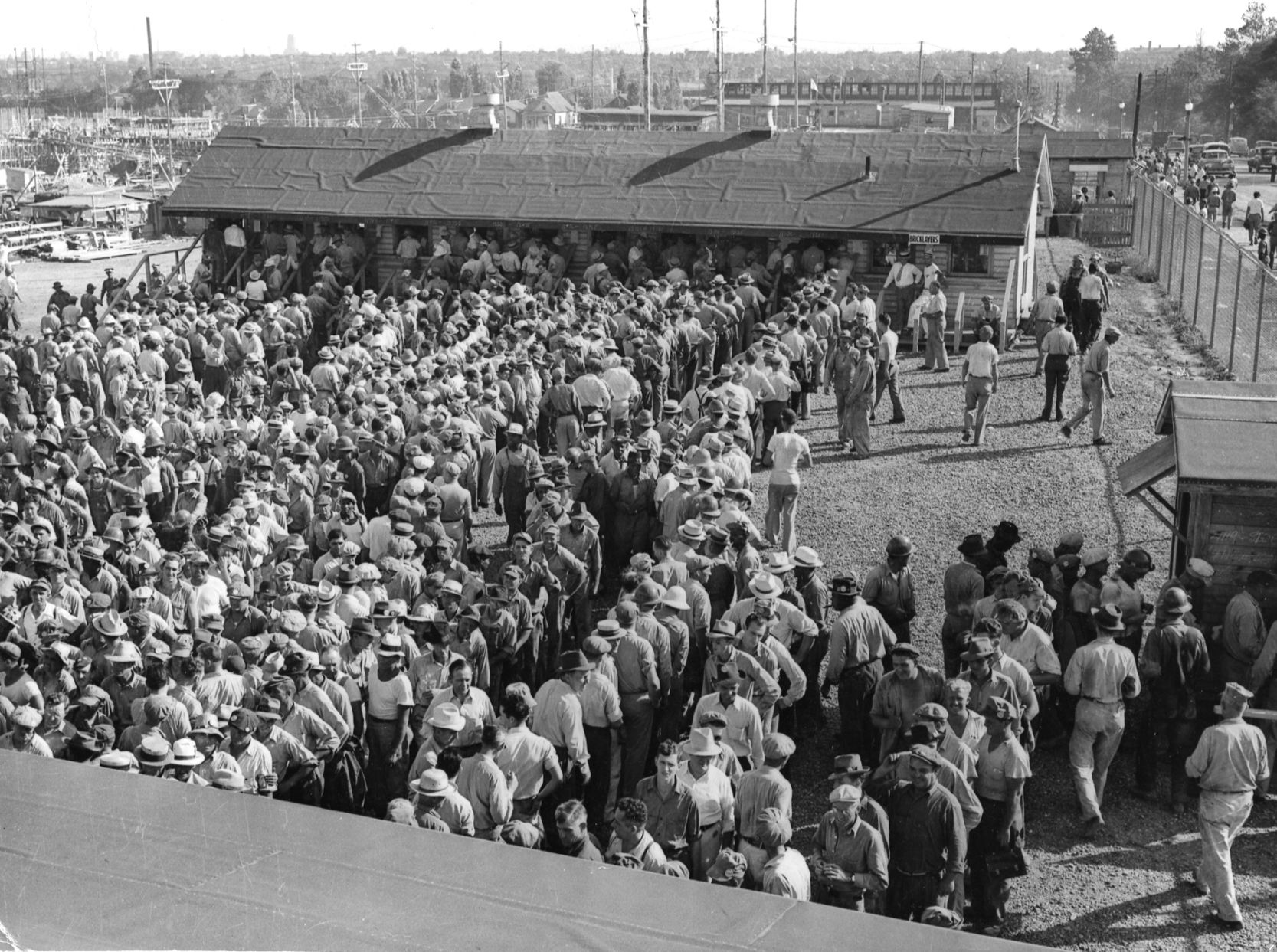

men looking for a job at the start of construction in January 1941

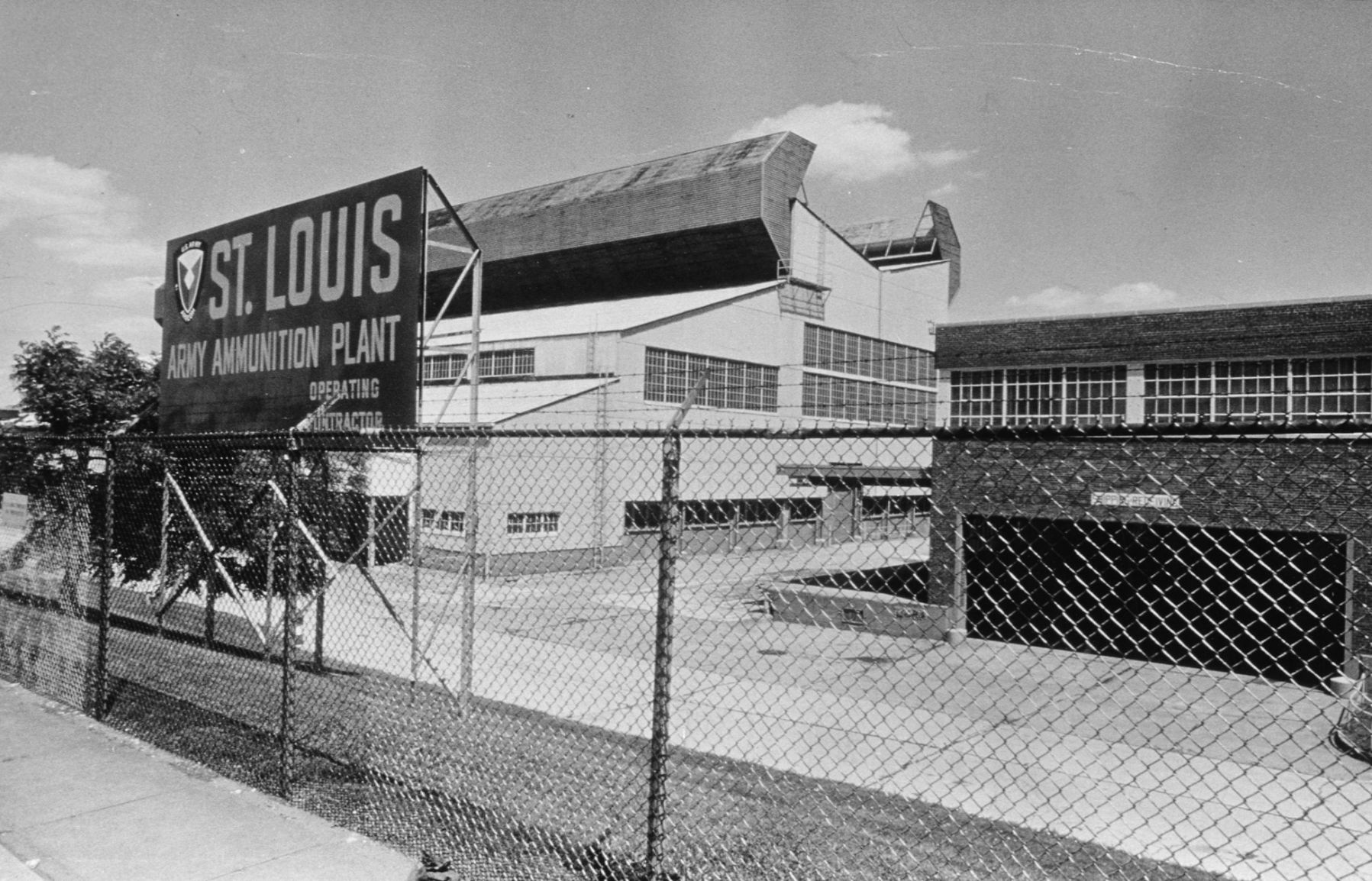

the government would own it, but Western Cartridge Co. of Alton, Illinois would administer the plant.

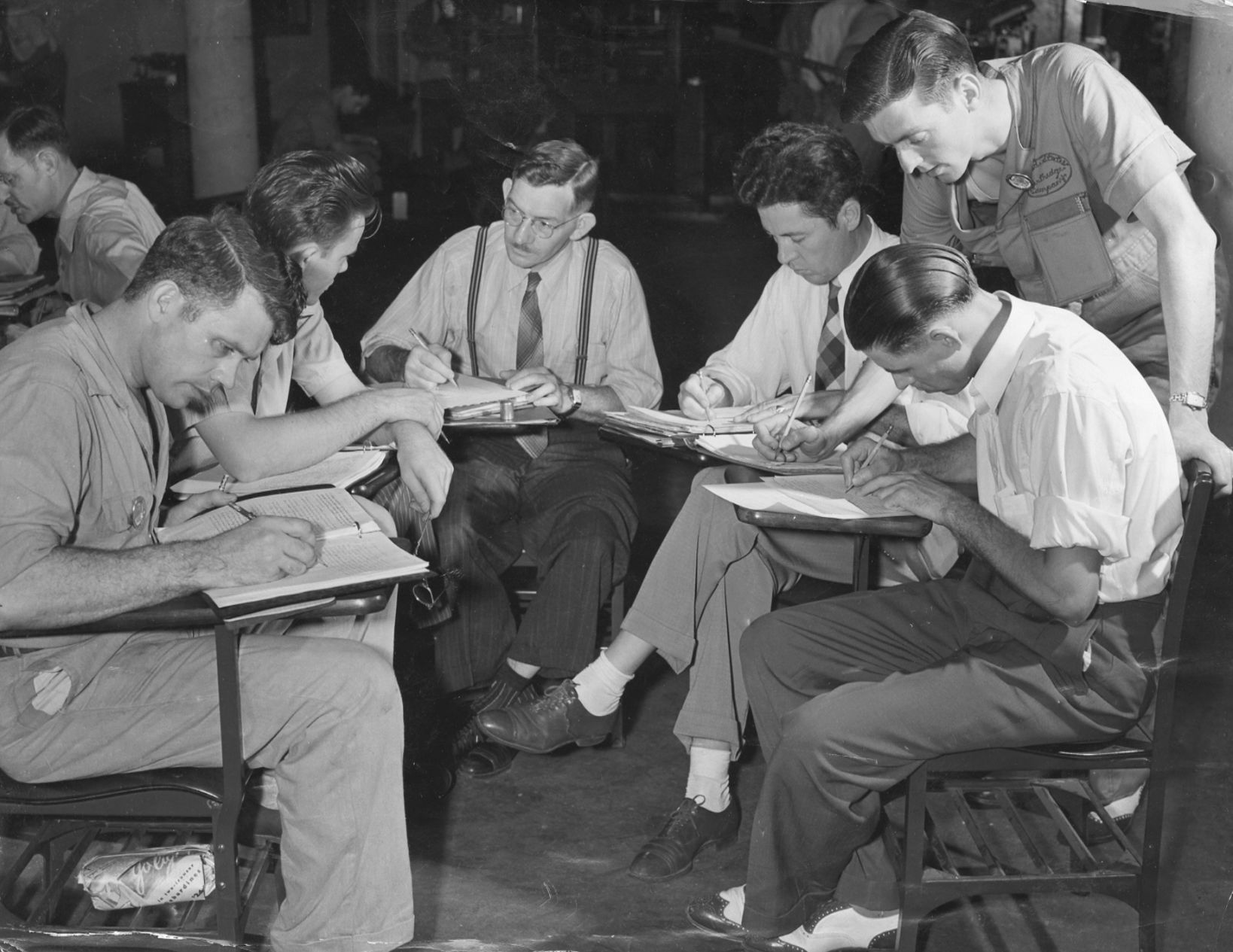

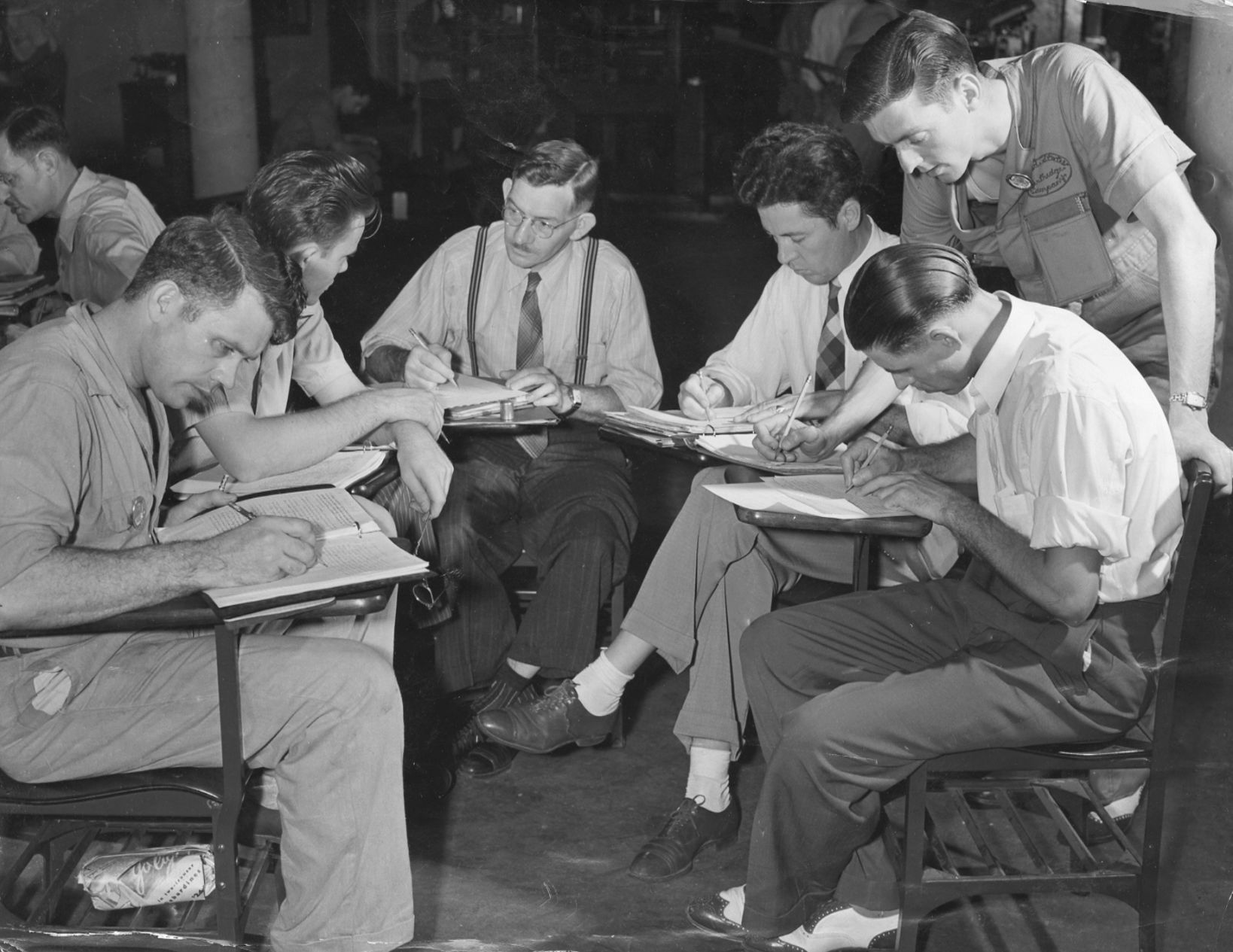

trainees took classes in ammunition-making at a school that Western Cartridge set up. The plan was to train 2,100 supervisors and machine inspectors for the startup of the plant, which was still under construction at a furious pace.

Brigadier General Brehon Somervell, Army chief of construction, gives a pep talk to construction workers.

this is a picture of the progress made so far, as published in the newspaper on Sunday morning, Dec, 7, 1941...

that afternoon at 1:31 PM, news on the radio announced a sneak attack on Pearl Harbor by the Japanese.

production of cartridges began nine days later.

there were 10 forges and the plant produced 1 billion cartridges by October 1942, and its second billion six months later. there were periodic layoffs when production outpaced the supply of brass.

workers pack .50BMG in boxes of 10 before putting them in larger cases and shipping them off.

a worker solders shut a .30 cal ammo box before nailing down the lid on the wooden box.

a woman operates a machine that checks .50BMG cartridges for defects. her husband is serving in the Army overseas.

a maintenance worker works on a machine. he had been discharged from the Infantry and wears his Army jacket.

later, the government used some buildings to store military records.

production resumed during the Korean and Vietnam wars.

inspectors check casings of 175mm artillery shells during the Vietnam War

production ended permanently in 1969.

today, about 2,000 employees of federal ganencies such as the General Services Administration, Social Security, Veterans Affairs and the Department of Agriculture still use some buildings in the complex.

the foundry was demolished in 2007.

Stamping machines punched cartridge casings from brass sheets. Automatic loaders rammed in powder and slugs. Boxes clanged along conveyors. Test firings added to the whirling racket.

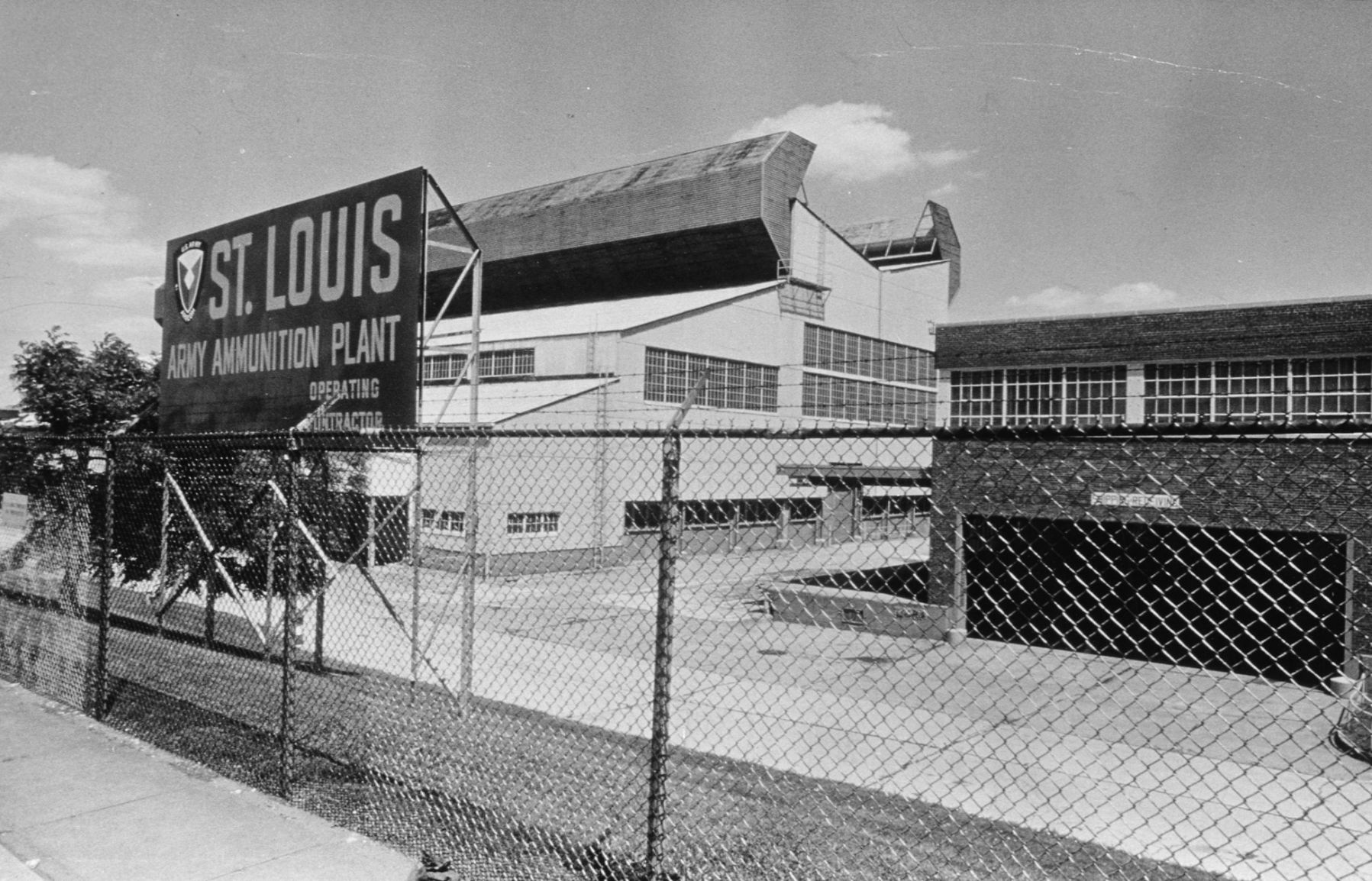

So it went 24 hours a day, seven days a week during World War II at the St. Louis Ordnance Plant, the world's largest maker of .30-caliber and .50-caliber ammunition for rifles and machine guns. At its busiest, in summer 1943, nearly 35,000 people worked on the 291-acre complex of 300 buildings and bunkers at 4300 Goodfellow Boulevard, on the city's northwest edge. Production peaked at 250 million cartridges a month.

Workers ate in 22 in-house cafeterias. They rode "Cartridge Plant" bus routes. Women made up half of the workforce.

as of 1940 the United States had not yet entered the war, but were helping the Allies. it would cost $110,000,000 to build the plant: 300 buildings on 291 acres, employing 17,000 construction workers.

men looking for a job at the start of construction in January 1941

the government would own it, but Western Cartridge Co. of Alton, Illinois would administer the plant.

trainees took classes in ammunition-making at a school that Western Cartridge set up. The plan was to train 2,100 supervisors and machine inspectors for the startup of the plant, which was still under construction at a furious pace.

Brigadier General Brehon Somervell, Army chief of construction, gives a pep talk to construction workers.

this is a picture of the progress made so far, as published in the newspaper on Sunday morning, Dec, 7, 1941...

that afternoon at 1:31 PM, news on the radio announced a sneak attack on Pearl Harbor by the Japanese.

production of cartridges began nine days later.

there were 10 forges and the plant produced 1 billion cartridges by October 1942, and its second billion six months later. there were periodic layoffs when production outpaced the supply of brass.

workers pack .50BMG in boxes of 10 before putting them in larger cases and shipping them off.

a worker solders shut a .30 cal ammo box before nailing down the lid on the wooden box.

a woman operates a machine that checks .50BMG cartridges for defects. her husband is serving in the Army overseas.

The plant was an early civil-rights flashpoint. After 300 black protesters seeking production jobs marched outside on June 20, 1942, managers agreed to put blacks on a segregated production line. Not until December 1944, over the protests of some white workers, did the government order full integration.

Some of the 300 black protesters who marched along Goodfellow Boulevard in front of the Ordnance Plant on June 20, 1942, seeking better-paying production jobs. The plant employed blacks for janitorial and other support jobs. One week earlier, the plant had laid off 148 blacks after their work as landscapers was completed. After the protest, the plant announced that it would hire blacks to run one of the production lines, keeping black and white production workers segregated. It stayed that way until December 1944, when the government ordered the plant to fully integrate. Many white workers objected to that idea and, at a meeting of the Electrical, Radio and Machine Workers Local 825, overturned their leaders' resolution to support integration. But the government order prevailed, allowing more blacks to be hired.

a maintenance worker works on a machine. he had been discharged from the Infantry and wears his Army jacket.

by summer 1943, at the height of production, 34,338 people worked there, making .30-caliber and .50-caliber ammunition for American soldiers and aviators. it was the world's biggest small-arms ammunition plant, and turned out 6.7 billion cartridges during the war, 40 percent of what America fired in anger. With hires and departures over the war years, 86,264 people held jobs at the Ordnance Plant.

...

And then it ended. On June 27, 1945, managers announced they would cease production Sept. 1. Layoffs began the next week for the 16,000 remaining workers, who could still churn out 140 million cartridges a month.

Scoffing at assurances of work elsewhere, union chief Robert Logdson said, "Workers can't eat talk. They must have jobs." But everyone knew the day would come. Adolf Hitler was dead two months. American Marines and soldiers were cornering the last defenders on Okinawa. Japan lay ahead, but American bases were bursting with cartridges.

The St. Louis Ordnance Plant had made 6.7 billion of them.

later, the government used some buildings to store military records.

production resumed during the Korean and Vietnam wars.

inspectors check casings of 175mm artillery shells during the Vietnam War

production ended permanently in 1969.

today, about 2,000 employees of federal ganencies such as the General Services Administration, Social Security, Veterans Affairs and the Department of Agriculture still use some buildings in the complex.

the foundry was demolished in 2007.

Comments

This ammunition plant, just over the mountain from me, is still in operation and is the only North American manufacturer of nitrocellulose. My father in law retired from there.

https://www.baesystems.com/en-us/product/radford-army-ammunition-plant

For a while, employees could purchase Alliant reloading powder at a big discount.

My mother worked at a gun manufacturing plant during WWII. She inspected 50 cal. machine gun barrels for production defects. She said the plant was run by almost all women.

From running scrap metal drives to buying war bonds to sacrificing many day to day usual prewar activities like unlimited travel (gasoline was rationed). Even the fare around the dinner table was limited due to the needs for those serving on the line. The people of this country all worked together and sacrificed much for a common cause.

It was truly a time where these United States were UNITED!

+1

I wonder how long it would take to build and staff these factories today. Probably never find enough millennials that would work at what they would consider a menial job. Also with the things like environmental impact statements, passing a budget, making sure to hire a minority contractor and other government hoops to jump through it would take decades to build and staff. Bob

The Greatest Generation.

Dad rarely talked about the war. He just said something like "my job was to keep the Sherman {tank} running". He fought with the 5th Army.

Mom would say "I just got up a little earlier each mourning to make donuts for the "Boys".

Her raising a family of 6 kids after the war must have been easy. She already fed and cared for 600 "Boys".

George Reeves was no match for them....................

Combat Vet VN

D.A.V Life Member

Another large ammo plant is Lake City, Missouri. It is still in production. It is right at 4,000 acres and makes current NATO ammunition. It has gone through several company operators. For a long time it was ran by DuPont/Remington, but they lost the contract to Martin Marriata/Olin. Several guys I worked with were transferred there from the DuPont plant here in Topeka. Here's a link to that plant.

https://en.wikipedia.org/wiki/Lake_City_Army_Ammunition_Plant