In order to participate in the GunBroker Member forums, you must be logged in with your GunBroker.com account. Click the sign-in button at the top right of the forums page to get connected.

How do you select right bullet for your gun?

Sorry about the big pic.

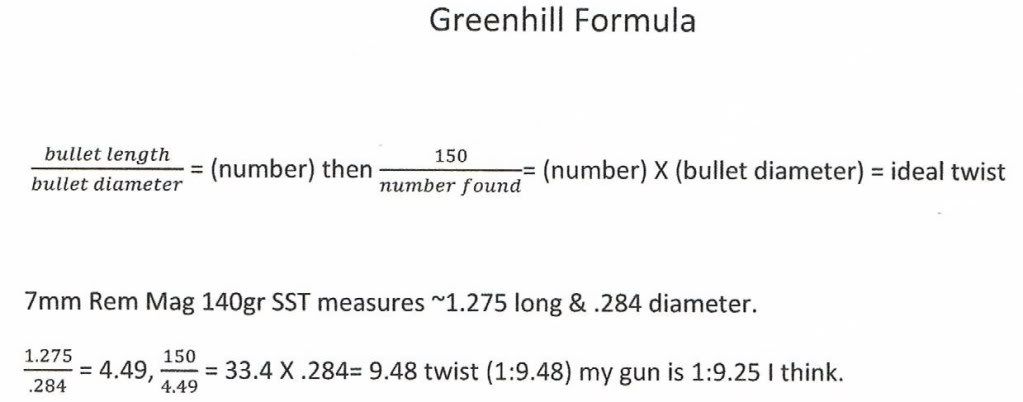

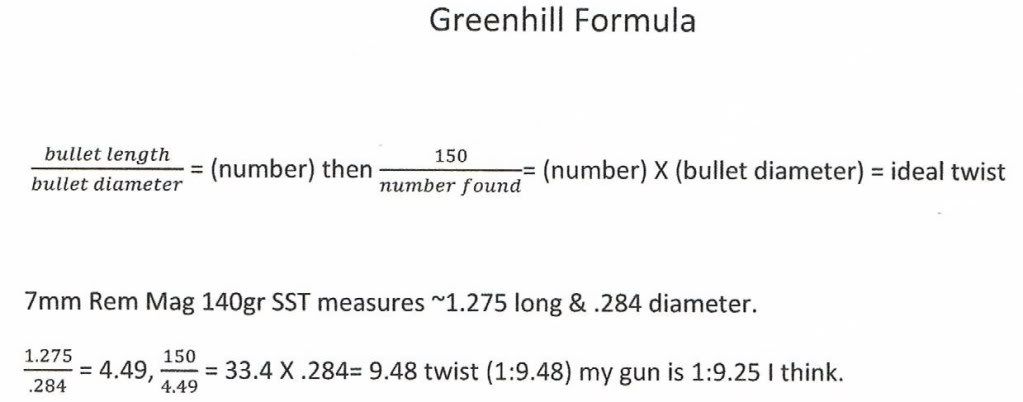

I read an article that offered a mathmatical way to find the best bullet for your gun.

I'll try to sum it up best I can with the formula and an example.

It said that by doing some math to find some numbers you could use those numbers and dividing them with 150 to select the best bullet weight for your know barrel twist.

I know many people will add that bearing surface of a bullet & bullet ogive will make a difference in selction.

I had 2 bullets I could choose from for the example in 7mm 140gr. One was Sierra 140gr spit BT & the other was a Hornady 140gr(139)SST that I used.

The Hornady was longer than the Sierra in OAL, but it's bearing surface was proportionaly longer too.

People use the tried and true method of shoot your gun and see what it likes as a good indicator.

Hopefully this will give some ideas on a place to start.

I know .223 is brought up alot with this type of question.

I read an article that offered a mathmatical way to find the best bullet for your gun.

I'll try to sum it up best I can with the formula and an example.

It said that by doing some math to find some numbers you could use those numbers and dividing them with 150 to select the best bullet weight for your know barrel twist.

I know many people will add that bearing surface of a bullet & bullet ogive will make a difference in selction.

I had 2 bullets I could choose from for the example in 7mm 140gr. One was Sierra 140gr spit BT & the other was a Hornady 140gr(139)SST that I used.

The Hornady was longer than the Sierra in OAL, but it's bearing surface was proportionaly longer too.

People use the tried and true method of shoot your gun and see what it likes as a good indicator.

Hopefully this will give some ideas on a place to start.

I know .223 is brought up alot with this type of question.

Comments

The twist of a barrel has nothing to do with its length.

I did some other bullets too. Just to give you an idea. These all .284 mind you.

162gr 1:8.46

154gr 1:8.96

130gr 1:10.29

You see were this is going.... More weight less twist. Less weight more twist.

140gr was 1:9.48 which is very close to the 1:9.25" I have. I guess

you could say that that is the starting point for an ideal bullet

for my gun.

Also bear in mind that the LONGER the bullet, the FASTER the twist rate (as expressed by a SMALLER number). A 1:10" twist is slower than a 1:8" twist. Calculations for twist rate are based on length of the bullet not the weight.

From another source:

Twist Rate

Bullet stability depends primarily on gyroscopic forces, the spin around the longitudinal axis of the bullet imparted by the twist of the rifling. Once the spinning bullet is pointed in the direction the shooter wants, it tends to travel in a straight line until it is influenced by outside forces such as gravity, wind and impact with the target.

Rifling is the spiral or helix grooves inside the barrel of a rifle or handgun. These grooves were invented a long time ago, perhaps as early as the 14th century. However, the smooth bore, using the round ball, was the choice of weapons for warfare even through the American Revolutionary war. The smooth bore musket could be loaded faster than the rifle and didn't foul, as bad, with the combustion products of black powder.

The rifling grooves helix is expressed in a twist rate or number of complete revolutions the grooves make in one inch of barrel length. A 1in10 or 1:10 would be one complete turn in 10 inches of barrel length.

How important is twist rate? David Tubb, a winner of several NRA High Power Rifle Championships, was using a .243 rifle with a 1 in 8.5 twist barrel. He wasn't able to get consistent accuracy until he changed to a rifle barrel with a 1 in 8 twist. The ?" twist change made all the difference between winning or losing the match.

A term we often hear is "overstabilization" of the bullet. This doesn't happen. Either a bullet is stable or it isn't. Too little twist will not stabilize the bullet, while too much twist, with a couple of exceptions, does little harm. Faster than optimum twists tend to exaggerate errors in bullet concentricity and may cause wobble. The faster twist also causes the bullet to spin at higher rpm, which can cause bullet blowup or disintegration because of the high centrifugal forces generated. For example, the .220 Swift, at 4,000 fps., spins the 50-grain bullet at 240,000 rpm.

One of the first persons to try to develop a formula for calculating the correct rate of twist for firearms, was George Greenhill, a mathematics lecturer at Emanuel College in Cambridge, England. His formula is based on the rule that the twist required in calibers equals 150 divided by the length of the bullet in calibers. This can be simplified to:

Twist = 150 X D2/L

Where:

D = bullet diameter in inches

L= bullet length in inches

150 = a constant

This formula had limitations, having after all been developed for artillery, but worked well up to and in the vicinity of about 1,800 f.p.s. For higher velocities most ballistic experts suggest substituting 180 for 150 in the formula. The twist formulas used in the Load From a Disk program, featured at this web site, uses a modified Greenhill formula in which the "150" constant is replaced by a series of equations that allow corrections for muzzle velocity from 1,100 to 4,000 fps. (Also note that the newer VLD bullets require some additional formula work to account for the higher BC value and how they perform. Originally we were using the G1 form but have switched to the G7. added by me)

The Greenhill formula is simple and easy to apply and gives a useful approximation to the desired twist. The Greenhill formula was based on a bullet with a specific gravity of 10.9, which is about right for the jacketed lead core bullet. Notice that bullet weight does not directly enter into the equation. For a given caliber, the heavier the bullet the longer the bullet will be. So bullet weight affects bullet length and bullet length is used in the formula.

To measure the twist of a barrel, use a cleaning rod and a tight patch. Start the patch down the barrel and mark the rod at the muzzle. Push in the rod slowly until it has made one revolution, and then make a second mark on the rod at the muzzle. The distance between marks is the twist of your barrel.

To see how this works out, assume you bought a .222 Remington rifle and you measured the twist rate as described above. The twist was 1 in 14. You have two .224 bullets you want to use, the 70-grain Speer SPS and the 50-grain Hornady SX. The Speer bullet measures .812 inches in length and the Hornady measures .520 inches. Using the formula above we calculate the following twist rate:

Speer 70-grain: 1 in 9

Hornady 50-grain: 1 in 14

These calculations show that the 50-grain bullet will be stabilized, but the 70-grain won't. Sure enough, when you try these bullets out, the 50-grain shoots _ MOA while the 70-grain won't group on the paper at 50 yards. Twist is important!

Here are a couple of plug and play calculators which are fairly straight forward to use:

http://www.tmtpages.com/twistrate.htm

http://kwk.us/twist.html

Best.

Wish I had happened apon your formula first, a lot simpler!

Could you show the last part of the formula so I can see the relation better?

Is it twist=150 x (diameter x 2/l) because I get 66.8 that way.

Edit: Eureka! I figured it out.[:I] twist= 150 x (dia squared/ L)

Using you new formula (with MV, bullet length, barrel twist, & diameter)

I get a twist of 11.25" & 12" for my 140gr bullet. I used both links to see the difference.

I also used the 180 as the constant unstead of 150.

162gr is pushing me toward 10" twist.

I think I maybe up to 170-175gr before I match the 9.25" twist in my gun,

not sure if I can except this as reliable info based on what I already proved shoots good in my gun?

And to comment about what the article said about weight not being the

important factor, it really is.

If the caliber stays the same, when bullet weight goes up, so does the length. They are directly proportional.

So, if the weight goes up the bearing surface goes up because the length has changed as well.

I completely understand why it & you mentioned it because it's not the factor that people should be most worried about.

The bearing surface length is the key. The longer the bearing surface, the tighter the twist needed.

Although MANY folks don't believe it exists, there is a point at which your bullet will NOT "go to sleep" before several hundred yards. I have a 6.5mm barrel in 1:8 twist that will NOT settle a bullet down before 400yds. It will print a 3/4" group until I shoot it at 400+yds. After that, I have targets showing touching bullet holes. I have shot it time and time again, at 100-200-300yds, and it won't group any better, but at 400yds, it touches bullet holes. THEY say it is an anomoly, but I sure own one. Mine is a 6.5x55 Ackely improved 1:8 twist, 4 groove barrel. She just ain't benchrest worthy before 400yds. After that, it's on[}:)]

Cylclonus,

I did some other bullets too. Just to give you an idea. These all .284 mind you.

162gr 1:8.46

154gr 1:8.96

130gr 1:10.29

You see were this is going.... More weight less twist. Less weight more twist.140gr was 1:9.48 which is very close to the 1:9.25" I have. I guess

you could say that that is the starting point for an ideal bullet

for my gun.

I think you've got that backwards, bambambam....more weight, MORE twist. You're showing RATE of twist per inch, so the higher number actually means LESS twist. 1/10" is LESS twist than 1/8".

Folks used to be able to use the greenhill formula and be "spot on" for projectile weight,..but in the last few decades, we have seen a great advance in bullet design which includes changing bearing surface length, and therefore, ogive design and boat-tail angles and lengths etc etc. Remember, if you increase a bearing surface's length, the nose must be sleeker as must the tail,..BECAUSE in the end, it still has to weigh the same[;)]